Infrastructure

Our units are spread over areas of 185,000 square feet and 195,000 square feet with a covered plant area of 135,000 square feet and 61,500 square feet each, including additional space for further expansion.

Pushkar Techno Pvt. Ltd. has a wide range of automated & semi-automated machines enabling us to manufacture a wide range of items as per the specifications provided by our customers.

We also manufacture pressed, fabricated, and machined sheet metal components and assemblies for automobiles. In-house designing and manufacturing of dies and fixtures are done to manufacture products as per the specifications provided by our customers.

For its sheet metal pressing division, Pushkar Techno Pvt. Ltd. has an infrastructure for pressing components up to 1000 tons and a 3100mm bed size. The machining facility includes:

- 8 Automated VMC and CNC Machines

- 4 Mechanical Power Press (1000 tons)

- 3 Mechanical Power Press (500 tons)

- 4 Mechanical Power Press (400 tons)

- 4 Mechanical Power Press (200 tons)

- 8 Mechanical Power Press (150 tons)

- 8 Mechanical Power Press (100 tons)

- 4 Hydraulic Press (300 tons)

- EOT Cranes

- Brake press

- Shearing machines

- Welding machines

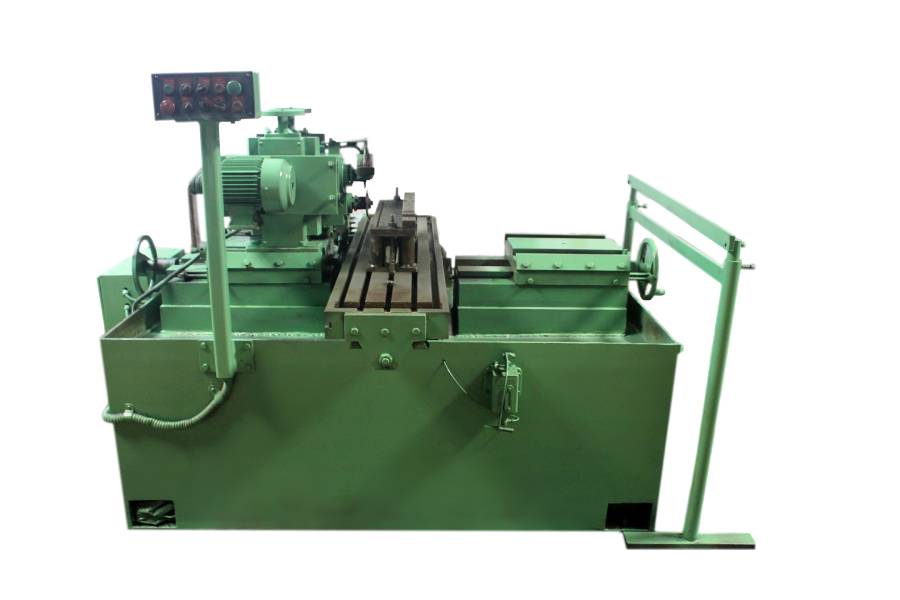

At our present setup, we have a manufacturing facility for different types of idler rollers and frames for belt widths ranging from 500mm to 2500mm. The following machines are used in the manufacturing of idler rollers:

- Pipe & Shaft Cutting Machines

- Hydraulic Forehead Shaft Milling/Slotting Machines

- Hydraulic Centerless Cylindrical Grinding Machines

- Hydraulic Pipe Recessing Machines

- Double Head Automatic Rotary Welding Machines

- Hydraulic Bearing Pressing Machines

We have a designated division that caters to finishing processes such as 10 tank pre-treatment and phosphating process, CED Coating (as per customer requirement), Finish Painting and Powder Coating.

For its Heavy Fabrication & Machining division, Pushkar Techno Pvt. Ltd. is equipped with advanced infrastructure to support large-scale, high-precision fabrication and machining. The facility includes:

- 5-Axis CNC Vertical Machining Centres

- CNC AMADA Laser Cutting Machine

- CNC 5-Axis Plasma Cutting Machine

- CNC Oxy Cutting Machine

- Rolling Machine

- Robotic Welding Machine

- Stress Relieving Furnace

- Shot Blasting and Painting Facility

- CNC Wire Cutting Facility

Testing Facilities

Pushkar Techno Pvt. Ltd. ensures the highest quality standards through a robust in-house testing infrastructure for both automotive components and the heavy fabrication & machining division. The following tests and equipment are used:

For Automotive Components:

Dry Film Thickness (DFT):

- Measured using a digital DFT probe to ensure accurate coating thickness.

- Primer: 30–40 microns | Finished product: 70–80 microns | CED coating: 60 microns.

Adhesion Test:

- A 1cm × 1cm matrix with 1mm squares is created; cello tape is applied and peeled.

- No more than 5 boxes should show damage.

Methyl Isobutyl Ketone (MIBK) Test:

- Painted surface is rubbed with chemical for 60 strokes.

- Paint should not peel or discolour.

Nugget Test:

- Welded samples are hammered until separation.

- The parent material should shear, not the weld zone.

Carbon Test:

- After every 100 welds, carbon impressions of tips are taken.

- Diameter should be ≥6mm, and the shape must not be round.

Universal Testing Machine (UTM):

- IS-standard test slabs are subjected to tensile load.

- Failure load is compared to the material’s rated strength.

For Heavy Fabrication & Machining Division:

- Provides high-precision 3D measurement of complex geometries.

- Ensures dimensional accuracy of large fabricated parts.

- Used for checking surface hardness of ferrous and non-ferrous components.

- Selection of scale depends on material type and finish.

- Evaluates the finish quality of machined surfaces.

- Ensures conformance to specified Ra values.

- Analyzes the chemical composition of metal alloys.

- Ensures the correct grade and purity of raw materials.

- Detects internal flaws in welds and castings non-destructively.

- Useful for thick sections and complex weld joints.

- Uses magnetic particle inspection to detect surface and subsurface cracks.

- Ideal for ferromagnetic materials and weld zones.

- Surface crack detection on non-ferrous and non-magnetic metals.

- Provides fast, visible results using dye and developer.

- On-site hardness verification for large or mounted components.

- Handy for post-fabrication inspection.

For Idlers and Rollers, the following tests are carried out:

Water Test:

- Water is sprayed on the assembled pulley at a pressure of 1kgf for 30 minutes.

- The roller is dismantled to check water ingress in the bearing area.

Dust Test:

- The roller is subjected to a dusty atmosphere for 30 minutes.

- The roller is dismantled to check dust ingress in the bearing area.

Friction Test:

- The rollers are mounted on the testbed and are made to rotate at 1200 rpm and are then allowed to come to a standstill.

- The elapsed time is used to calculate the coefficient of friction which should be less than 0.015.